Sáng sủa và hoàn hảo, làm sạch hiệu quả các bề mặt kim loại lớn và phức tạp, tiết kiệm, thân thiện với môi trường và mang lại lợi nhuận

Continuous laser cleaning machine0,08mm

Spot Diameter

10-60mm

Adjustable scanning width

10-100 (%)

Power adjustment range

2000 watts

Maximum laser power

Performance advantages

Cleaning large areas

Low operating costs

Non-contact cleaning

Manufacturing safety

Experience the superior productivity of laser welding now

Strong cleaning

Equipped with a branded fiber laser source, it can powerfully remove stubborn oil stains, rust layers, residual paint and other impurities on metal surfaces. Non-contact cleaning protects the base material, is free of chemical reagents, green and environmentally friendly, and does not require expensive and complex waste disposal links.

Cleaning large areas

Equipped with a continuous fiber laser, it is especially suitable for large-scale cleaning and high-speed cleaning. Easy to install and move, it can easily handle large-scale outdoor cleaning operations, including large steel structures, pipes, vehicle bodies, aircraft shells, metal towers, etc. Quickly removes surface impurities and shortens operating cycles.

Power on quickly

Combining extremely low operating costs, ergonomic design and excellent performance, the handheld laser head is comfortable to hold, easy to operate and can be used immediately after powering on. The lightweight body makes outdoor activities more convenient.

Lean and safe production environment

The machine is designed to clean all surfaces

Thick comprehensive protective case

The thick protective case is made from premium materials, providing optimal safety for your device. Helps protect your device from shocks, scratches and dust effectively.

Beautiful welds

Được điều khiển bằng hệ thống vi tính, máy hàn tự động đảm bảo độ chính xác cao trong việc điều chỉnh các thông số hàn như dòng điện, tốc độ hàn, vị trí hàn,... dẫn đến tạo ra mối hàn đồng đều, ít sai sót.Smart monitoring system

With the ability to monitor important operating parameters, this system helps you proactively monitor the condition of the machine, thereby providing timely maintenance and repair measures, increasing the life of the equipment.

The system is stable, has a long lifespan and requires no maintenance

Using an intelligent laser light path control system, the cleaning ability is much superior to traditional sandblasting and dry ice cleaning technology, making it one of the most effective surface treatment solutions. such as industrial cleaning, rust removal, paint removal. It is safe to operate and adapts to various complex working environments. The service life can reach 100,000 hours.

Automatically cleans thoroughly

The device is integrated with the KUKA robot control system to meet changing cleaning needs. 360° cleaning, cleaning of large objects and cleaning of hazardous areas can be easily achieved with one machine.

Precise cleaning of complex parts

suitable for various curved surfaces and special shapes, scan over a wide range, and freely switch between different light shapes such as straight lines and circles to achieve precise cleaning of areas specific areas and specific locations.

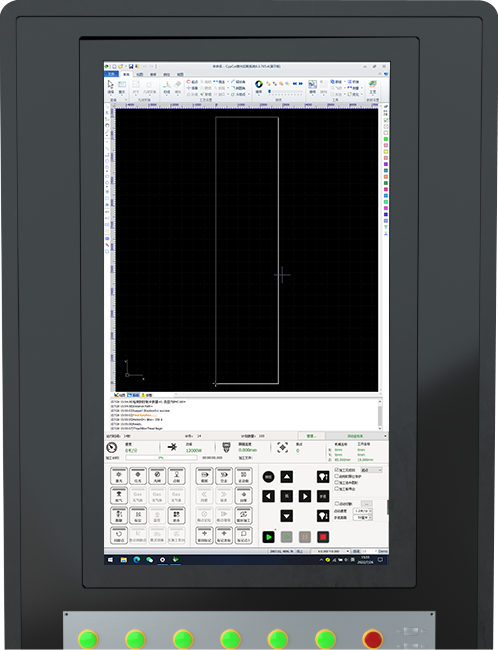

Smart operating system with touch screen

makes your cutting process intuitive and intuitive

From drawing to nesting to cutting the workpiece, it's all done with just a few clicks.

Improved safety

Actively avoid obstacles

Smart alarm system

Rear jitter plate

Super performance

visual remnants

Anti-vibration

Air tight loop control