Applications

New generation smart laser solution provider

Cut with laser

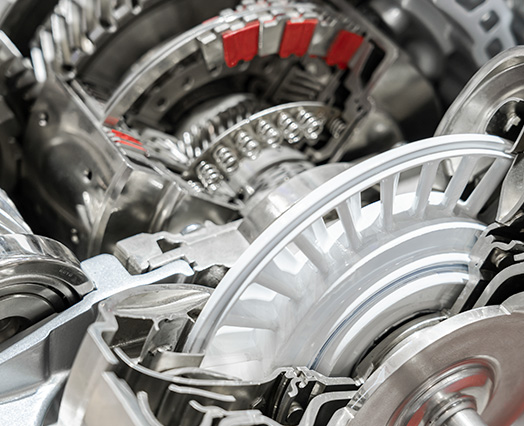

Vehicle industry

Electronic device

Kitchen

Agricultural machinery

Automotive Parts

Lithium batteries

Pacemaker

Closed relay

Laser welding

Shelves

Elevator

Kitchen

Car parts

Doors and windows

Cooking equipment

Làm sạch bằng laser

Loại bỏ gỉ thép

làm sạch vòi bồn rửa

Clean the mold

Clean brake pads

Clean the wheels

Loại bỏ gỉ sét bánh răng

Advantages of laser cutting, welding and cleaning

High precision

Cutting accuracy can be achieved ±0.01mm, eliminating more downstream processes.

High speed

Compared with traditional processes, it has higher cutting speed, especially when performing complex cutting operations with the same material thickness.

Excellent cutting surface quality

Whether cutting sheets, tubes or irregularly shaped materials, the cutting surface is smooth and burr-free.

High degree of automation

Almost no labor is required and labor costs are significantly reduced compared to traditional cutting methods.

Flexibility

Can be customized to meet the processing needs of different metal plates and tubes.

Energy saving and environmentally friendly

High processing precision and ultra-high photoelectric conversion speed provide significant savings in material costs and operating costs.

Equipped with a vacuum cleaner to help reduce pollution while keeping the working environment as clean as new.