The batch welding quality is outstanding, consistent, and the weld lines are beautiful and perfect

Fully automatic laser welding machine4 times

Increase speed

5mm

Maximum melting width

10mm

Maximum penetration (two-sided welding)

6000 watts

Maximum laser power

Performance advantages

Stability quality

Low operating costs

High flexibility

Manufacturing safety

Experience the superior productivity of laser welding now

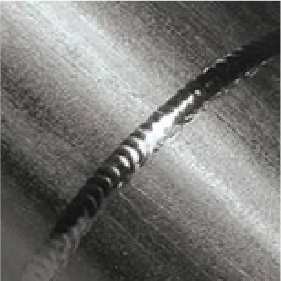

Beautiful welds and stable quality

CCD real-time monitoring system combined with special welding control software helps accurately locate the welding position and automatically focus on welding details, strong welds, and beautiful welds.

Efficient welding for mass production

Clamps and rotary devices can be added to realize batch automatic welding, greatly improving welding efficiency and obtaining better welding results.

High quality welding of complex parts

In addition to overlap welding, butt welding and conventional welding methods, welding at special angles and shapes can also be achieved by adding fixtures, which are more effective in welding rotationally symmetrical parts. Easily switch from welding mode to cutting mode by changing the nozzle.

Lean and safe production environment

The machine is designed with a completely sealed structure, equipped with a specialized laser protection observation window. The dust extraction system strictly complies with EU environmental standards.

Thick comprehensive protective case

The thick protective case is made from premium materials, providing optimal safety for your device. Helps protect your device from shocks, scratches and dust effectively.

Beautiful welds

CCD real-time monitoring system combined with special welding control software helps accurately locate the welding position and automatically focus on welding details, strong welds, and beautiful welds.Smart monitoring system

With the ability to monitor important operating parameters, this system helps you proactively monitor the condition of the machine, thereby providing timely maintenance and repair measures, increasing the life of the equipment.

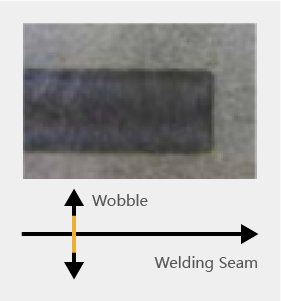

The light output is highly flexible with a variety of shapes

Equipped with an advanced rotating welding head, the left and right rotation amplitude can be set according to production needs, and the size is adjustable. There are many different light shapes, including points, lines, circles, triangles, figure 8s, and double O shapes. For materials prone to welding defects such as pores and cracks, the oscillating welding head can effectively optimize the welding process and minimize welding defects.

Circle

Linear

8 words

Double O shape

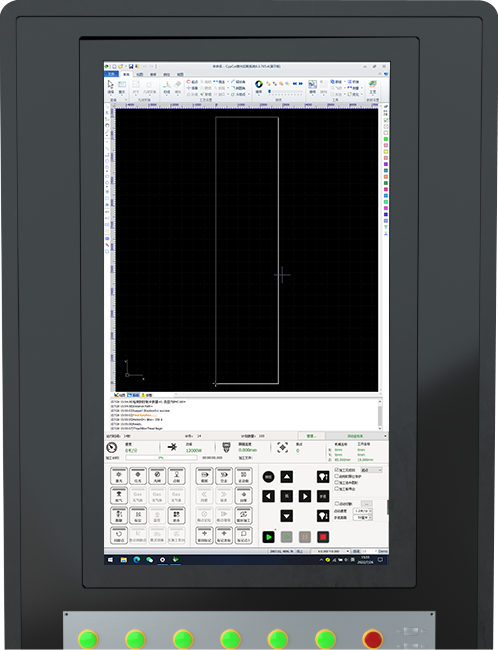

Smart operating system with touch screen

makes your cutting process intuitive and intuitive

From drawing to nesting to cutting the workpiece, it's all done with just a few clicks.

Improved safety

Actively avoid obstacles

Smart alarm system

Rear jitter plate

Super performance

visual remnants

Anti-vibration

Air tight loop control

Multi-angle welding robot operates flexibly

The introduction of six-axis fully automatic laser processing technology and the additional use of robotic arms allow flexible welding at many angles, reducing the rate of defective products while perfectly replacing manual operations. work in high-risk environments.Some products from the machine