From process to simplicity, Innovation in speed and quality makes multi-scenario welding more convenient.

Integrated handheld laser welding machine4 times

Increase speed

5mm

Maximum melting width

6mm

Maximum penetration (two-sided welding)

2000 watts

Maximum laser power

Performance advantages

It's easy to move

Low operating costs

Extremely fast welding

Manufacturing safety

Experience the superior productivity of laser welding now

The integrated laser system makes welding more flexible

The new generation all-in-one handheld laser welding machine integrates laser, chiller and software control, occupies a small area, is easy to move and can be used in many situations.

Unique rotating welding head has higher welding quality

The oscillating laser welding head combined with a highly interactive control system can perfectly handle larger detail error ranges and larger weld widths. The welding head uses ergonomic design, comfortable to hold and does not cause fatigue when working for a long time.

High quality welding of complex parts

In addition to overlap welding, butt welding and conventional welding methods, welding at special angles and shapes can also be achieved by adding fixtures, which are more effective in welding rotationally symmetrical parts. Easily switch from welding mode to cutting mode by changing the nozzle.

Lean and safe production environment

The machine is designed with a completely sealed structure, equipped with a specialized laser protection observation window. The dust extraction system strictly complies with EU environmental standards.

Thick comprehensive protective case

The thick protective case is made from premium materials, providing optimal safety for your device. Helps protect your device from shocks, scratches and dust effectively.

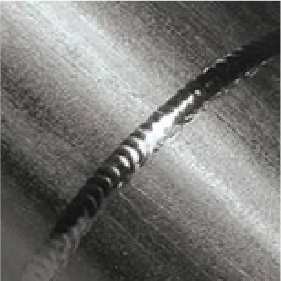

Beautiful welds

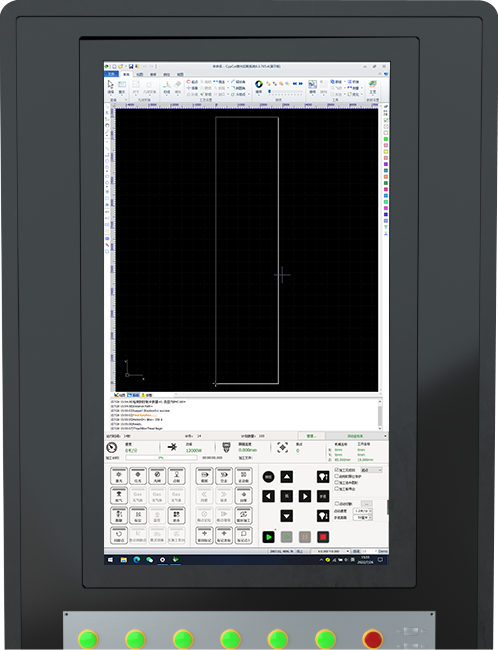

CCD real-time monitoring system combined with special welding control software helps accurately locate the welding position and automatically focus on welding details, strong welds, and beautiful welds.Smart monitoring system

With the ability to monitor important operating parameters, this system helps you proactively monitor the condition of the machine, thereby providing timely maintenance and repair measures, increasing the life of the equipment.

Protective safety clip

The device is equipped with a safety clip that does not touch metal and prevents light from leaking out, ensuring absolute safety for the operator.

Many welding modes

Non-contact welding, welding all kinds of objects anytime, anywhere. Many types of welding heads meet different welding needs such as spot welding, butt welding, overlap welding, vertical welding, flat fillet welding, internal and external fillet welding. Effectively solves welding problems of complex welds or irregular workpieces.

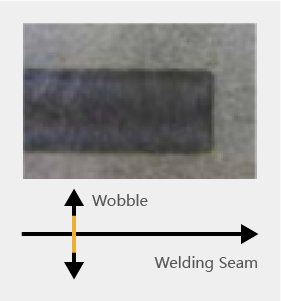

The light output is highly flexible with a variety of shapes

Equipped with an advanced rotating welding head, the left and right rotation amplitude can be set according to production needs, and the size is adjustable. There are many different light shapes, including points, lines, circles, triangles, figure 8s, and double O shapes. For materials prone to welding defects such as pores and cracks, the oscillating welding head can effectively optimize the welding process and minimize welding defects.

Circle

Linear

8 words

Double O shape

Smart operating system with touch screen

makes your cutting process intuitive and intuitive

From drawing to nesting to cutting the workpiece, it's all done with just a few clicks.

Improved safety

Actively avoid obstacles

Smart alarm system

Rear jitter plate

Super performance

visual remnants

Anti-vibration

Air tight loop control

Easily weld large objects across long distances

It comes with movable pulleys, breaking away from the limitations of a fixed workstation and allowing it to be moved freely in complex work situations. At the same time, the length of the optical fiber can be customized to achieve the ability to weld large objects and long-distance objects.

Automatic wire feeding and rotating welding perfectly handle wide welds

Smart wire-feed rotary welding technology can bridge larger gaps than autogenous welding and meet the needs of welding wider joints. Welding operations are not difficult due to fixture or workpiece errors, welding quality is stable, and wire feed speed is adjustable.

Quick start and easy operation

The handheld laser welding machine is easy to operate, can be used immediately when turned on, no need for professional staff to operate, beginners can quickly get started.

Multi-angle welding robot operates flexibly

The introduction of six-axis fully automatic laser processing technology and the additional use of robotic arms allow flexible welding at many angles, reducing the rate of defective products while perfectly replacing manual operations. work in high-risk environments.Some products from the machine